Production process of slotted pan head screws with large head

HOTFORGE INDUSTRIAL LIMITED is a professional fastener manufacturer, specializing in the production of threaded rods, bolts, nuts, washers and other mechanical forging parts. Our products are widely used in standards in petrochemical, aerospace, automotive production, construction and equipment manufacturing and other related industries. We are proud to provide customized solutions according to the specific needs of our customers.

The production process of slotted pan head screws with large head mainly includes the following steps:

1. Purchase raw materials hot rolled wire rod

2. Automatic wire drawing machine

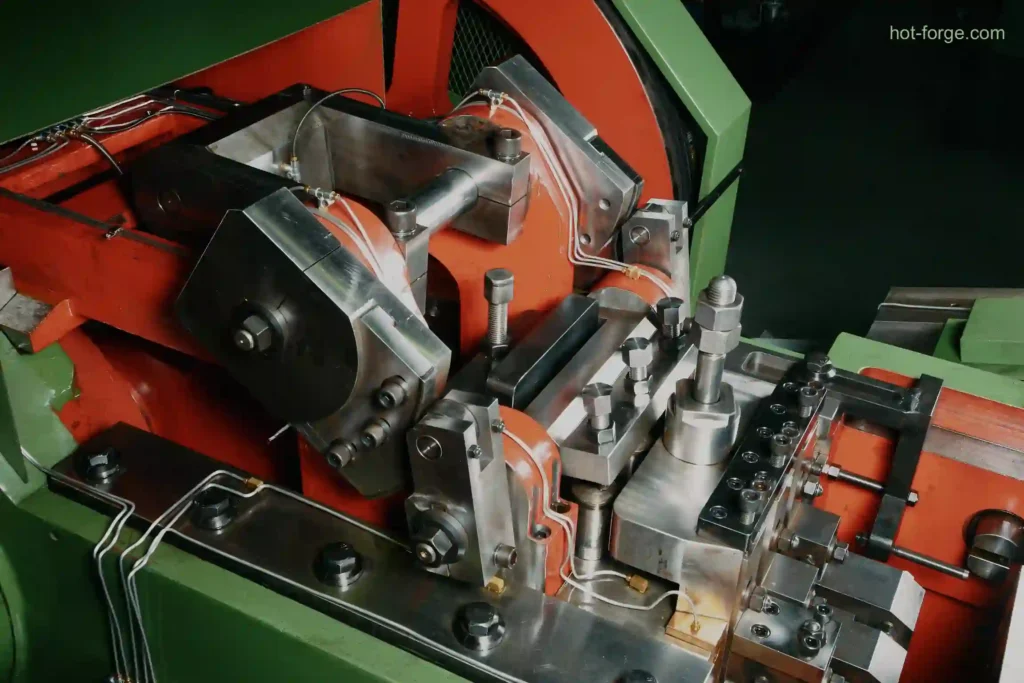

3. Screw cold heading machine

4. Bolt product heat treatment furnace

5. Bolt processing Rolling thread

6. Laser marking of bolt products

7. Packaging and delivery

Summary:

Slotted pan head screws DIN 921 production involves multiple steps such as raw material preparation, cold heading forming, wire rolling, heat treatment, surface treatment, inspection and testing, and packaging. Each step requires strict control to ensure that the quality and performance of the finished bolts meet the requirements. Can fully meet the project usage needs of users.

For more detailed specifications and models, you can refer to manufacturers’ websites or technical product catalogs.