Most Popular Flanges Styles

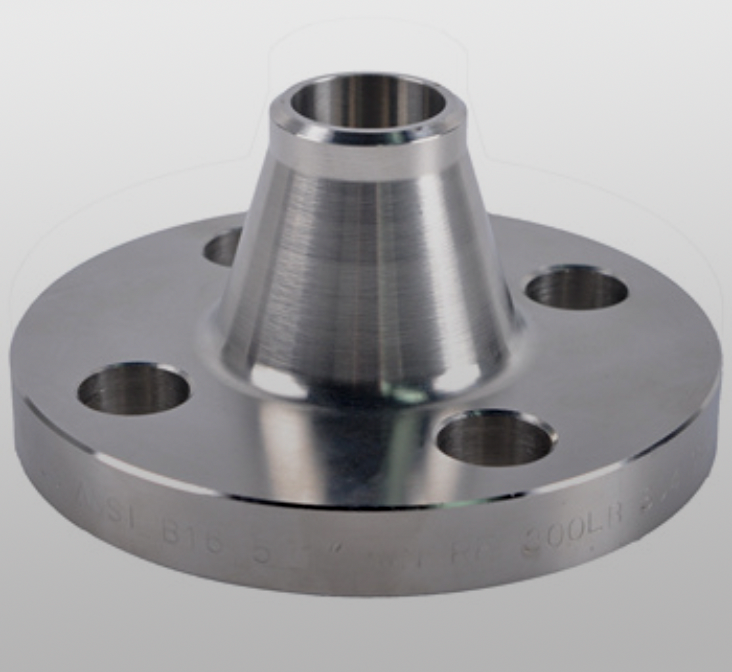

Weld Neck Flanges

Weld neck flanges are the most popular flange type with a neck extension with a weld bevel at the end. This type of flange is designed to butt weld directly to the pipe to provide a superior and relatively natural form connection. In larger sizes and higher pressure classes, this is almost exclusively the type of flange connection utilized. If only one bored flange style existed in modern applications, the weld neck would be your flange of choice.

Lap Joint Flanges

Lap Joint Flanges are a less requested type of flange with an extended hub and a machined radius at the base of the flat face. This curved radius allows for the placement of a pipe fitting known as a stub end. This type of flange is made to saddle over stub end fitting for rotation. The pair is an excellent choice for situations that require constant removal and reinstallation in order to inspect the connection. This combination allows for the rotation of the lap joint over the stub end for accurate bolting.

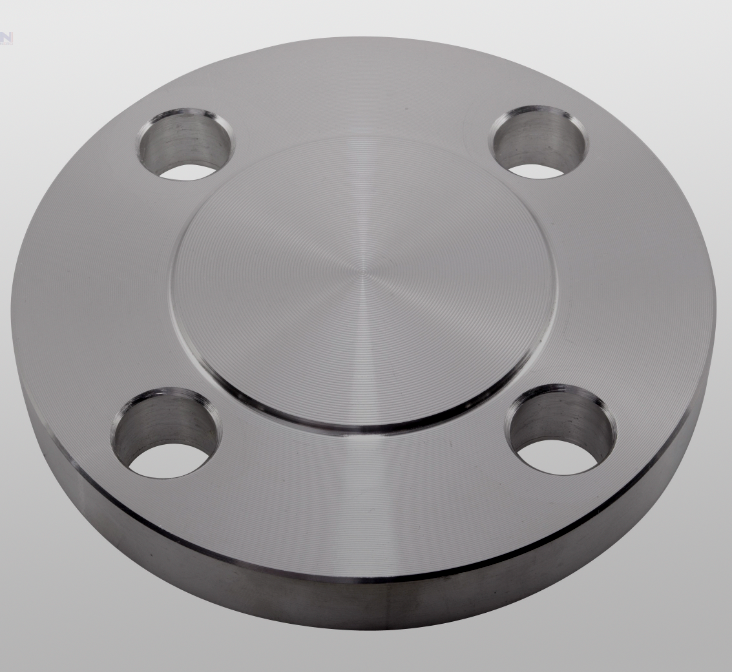

Blind Flanges

A blind flange is a solid steel piece with no bore (interior diameter) and is primarily designed to cap off a line. As the majority of flange connections allow for the passing through of air or fluid via an interior opening, blinds give the ends of pipe connections a well-formed termination point or rerouting of the media in question towards another portion of the pipe assembly. Opt for a blind flange in these cases, as well as in instances when a pipeline requires a future modification such as the installation of a valve or fitting to reroute flow.

Socket Weld Flanges

Socket weld flanges are a less common but equally effective connection for flanges that require less overall available space than a traditional weld neck flange, with a counterbore in the center to allow for a clean weld of pipe into the socket. Usually furnished in smaller nominal pipe sizes, these make an excellent alternative to weld necks and slip-ons when necessary.

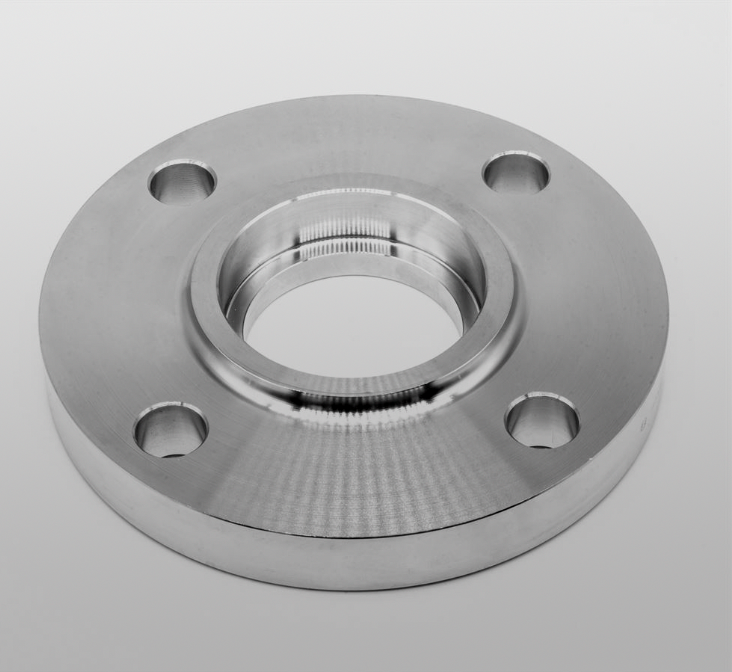

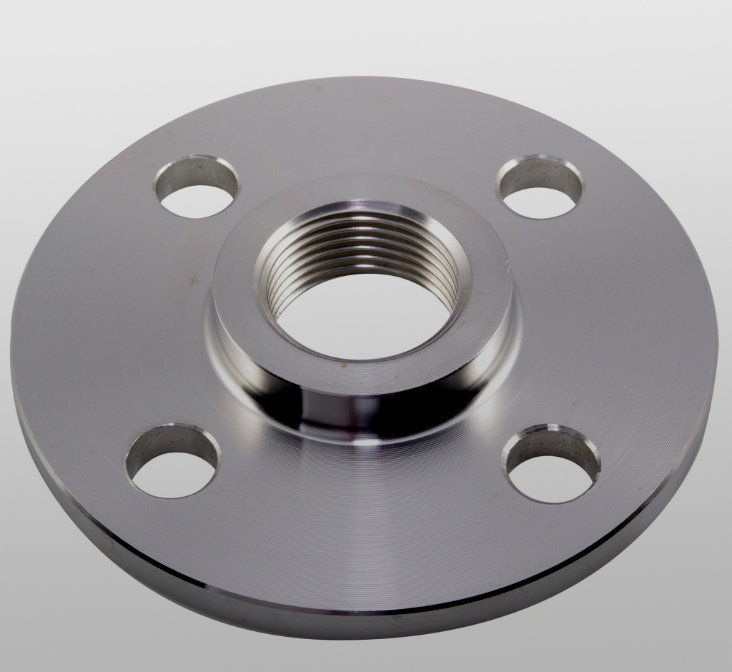

Threaded Flanges

Threaded flanges, also sometimes referred to as companion flanges/screw flanges / NPT flanges, contain a female NPT thread in the center for connection to male NPT threaded piping. Threaded flanges are common when creating reduced connections. Other thread styles are available for machining, aside from the standard NPT form as designated by the ASME B16.5 specification. and therefore allows the pipe to be adjusted in length relative to its position on the flange. The bore of the slip-on will give an ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection.

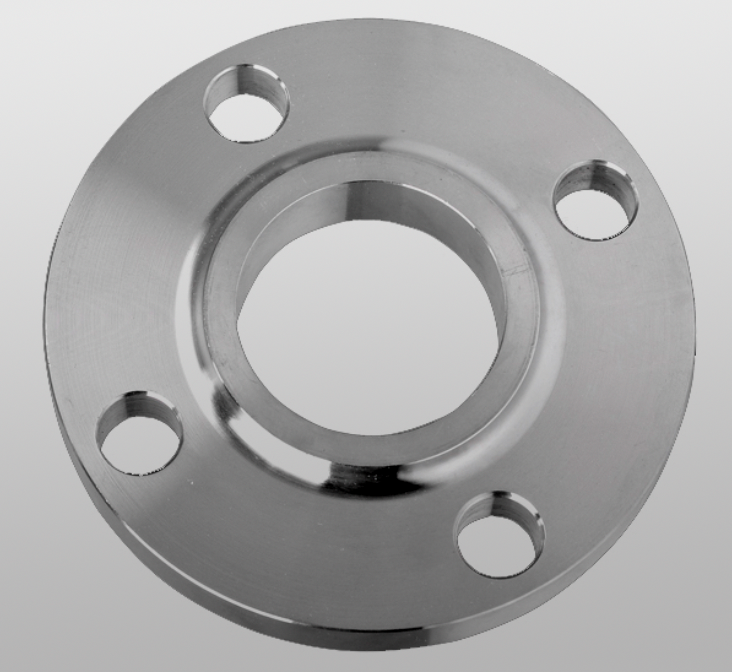

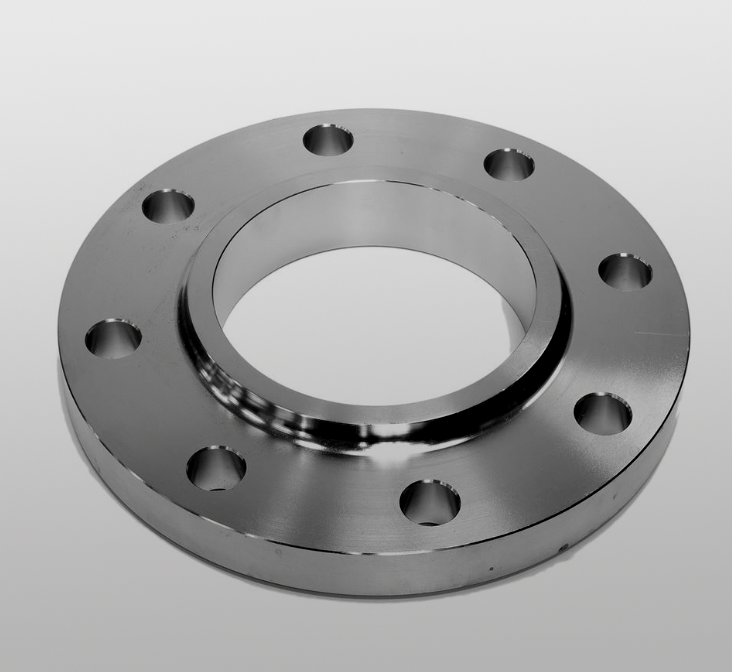

Slip-On Flanges

The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange. The bore of the slip-on will give an ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection.