As a trusted manufacturer of industrial fasteners, we specialize in producing high-quality HEX SETSCREWS and HEX NUTS made from premium materials that meet the toughest standards. Our products are specifically designed for applications requiring reliable performance, high tensile strength, and superior corrosion resistance. We use ASTM F468 UNS C65100 material for these fasteners, ensuring they can withstand harsh environments and demanding industrial applications.

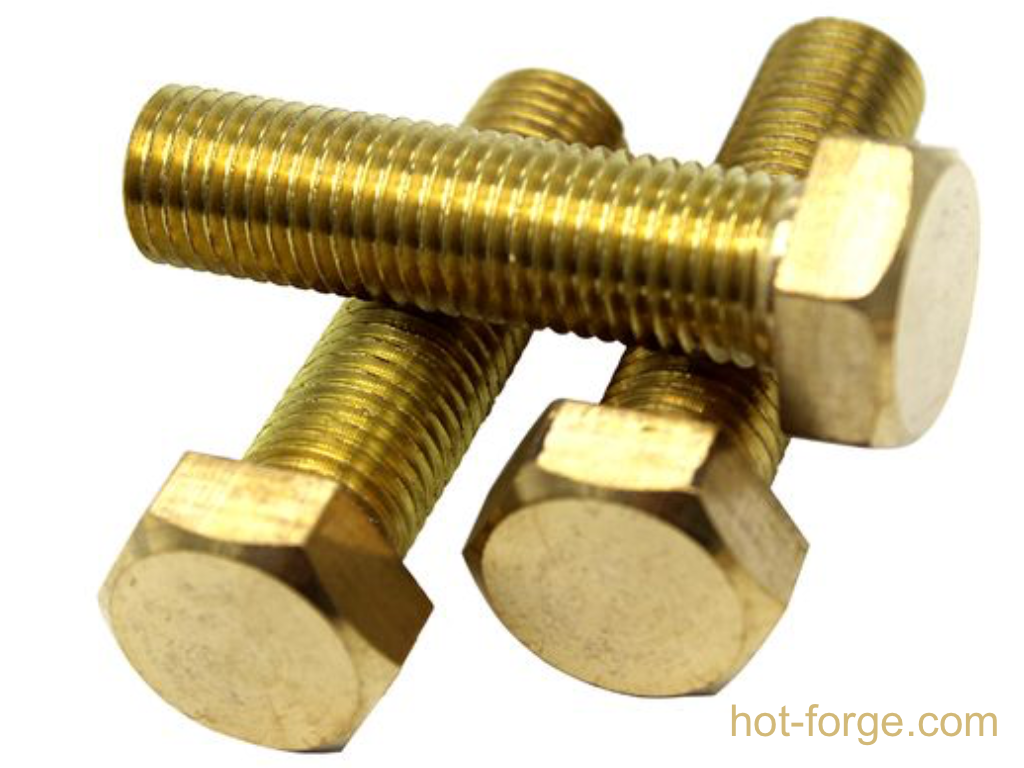

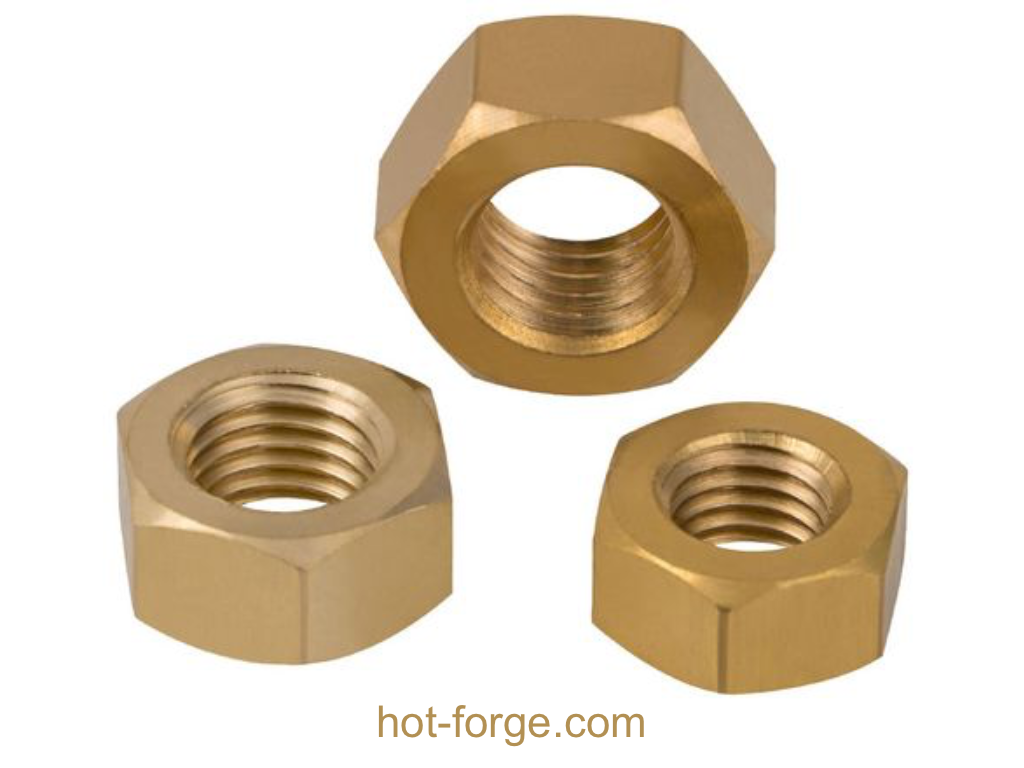

Our HEX SETSCREW and HEX NUT Products

Our HEX SETSCREWS and HEX NUTS are manufactured with precision, offering unparalleled reliability for a wide range of applications. These fasteners are ideal for industries such as construction, mechanical engineering, and heavy equipment, where secure fastening and long-lasting performance are paramount.

- HEX SETSCREWS: Also known as grub screws, these are used for securing components within machinery and assemblies. Our HEX SETSCREWS come in a range of sizes and lengths to suit different applications and are perfect for securing gears, pulleys, and other critical components.

- HEX NUTS: These are essential for completing threaded assemblies and ensuring a secure, tight fit. Our HEX NUTS are designed to work perfectly with our HEX SETSCREWS and other fasteners, ensuring that your assemblies stay firmly in place under various load conditions.

Material: ASTM F468 UNS C65100

Our HEX SETSCREWS and HEX NUTS are made from ASTM F468 UNS C65100, a high-quality material known for its excellent mechanical properties and exceptional corrosion resistance. This alloy, also referred to as C65100 or CDA 651, is a copper-based material with high tensile strength and great resistance to environmental factors such as moisture, chemicals, and extreme temperatures. It is ideal for use in applications where reliability and durability are critical.

Key benefits of ASTM F468 UNS C65100 include:

- Corrosion Resistance: The material’s high copper content makes it resistant to corrosion, making it suitable for marine environments and applications exposed to moisture or corrosive chemicals.

- High Tensile Strength: The alloy is designed to withstand high mechanical stresses, ensuring that the fasteners maintain their integrity even under demanding conditions.

- Non-Sparking: C65100 material is non-sparking, which makes it ideal for use in hazardous environments where ignition risk is a concern.

This material is widely used in industries like oil and gas, marine, and construction, where fasteners must endure high-stress and corrosive environments.

Manufactured to ASME B18.2.1 and ASME B18.2.2 Standards

Our HEX SETSCREWS and HEX NUTS are manufactured in strict adherence to the ASME B18.2.1 and ASME B18.2.2 standards, ensuring the highest level of quality and precision.

- ASME B18.2.1: This standard defines the specifications for hexagon head bolts, screws, and their dimensions. It ensures that all our fasteners are manufactured to exacting specifications, making them suitable for a wide range of industrial applications.

- ASME B18.2.2: This standard covers the specifications for hex nuts, including dimensional tolerances, strength requirements, and thread specifications. By adhering to this standard, we guarantee that our HEX NUTS provide a secure fit and reliable performance.

By manufacturing to these standards, we ensure that our products consistently meet customer expectations for quality, performance, and durability.

Applications of Our HEX SETSCREWS and HEX NUTS

Our high-performance HEX SETSCREWS and HEX NUTS are used across a variety of industries, including:

- Marine and Offshore: Due to their exceptional corrosion resistance, our fasteners are ideal for use in marine environments, ensuring long-lasting performance even in harsh conditions.

- Construction and Heavy Equipment: Our HEX SETSCREWS and HEX NUTS provide secure fastening for construction equipment, machinery, and structural assemblies.

- Aerospace and Aviation: The high tensile strength of C65100 material makes our fasteners suitable for critical aerospace applications.

- Oil and Gas: In this industry, fasteners must withstand extreme pressures and corrosive environments, making our ASTM F468 UNS C65100-based products the perfect solution.

Quality Assurance

At our manufacturing facility, we prioritize quality at every step of the production process. From material selection to final inspection, we ensure that our fasteners meet the highest industry standards. Each batch of HEX SETSCREWS and HEX NUTS undergoes rigorous testing, including dimensional checks, tensile testing, and corrosion resistance evaluations, to guarantee that our products meet the required performance standards.

Why Choose Our Fasteners?

- Superior Material: We use ASTM F468 UNS C65100 for its excellent mechanical properties, corrosion resistance, and durability, ensuring your assemblies last longer and perform better.

- Precision Manufacturing: Our fasteners are made in compliance with ASME B18.2.1 and ASME B18.2.2 standards, guaranteeing precise dimensions and secure fastening.

- Custom Solutions: We understand that every project is unique. Our engineering team is available to help customize our HEX SETSCREWS and HEX NUTS to meet your specific needs, ensuring perfect compatibility with your designs.

Contact Us

If you’re looking for high-quality HEX SETSCREWS and HEX NUTS made from ASTM F468 UNS C65100, we’re here to help. Contact our team today for product inquiries or to place an order. We are committed to providing fasteners that meet your exact requirements, backed by exceptional customer service.