What are the production processes of stainless u-bolts?

The production of stainless U bolts involves several steps that transform raw stainless steel materials into the final U-bolt shape with the desired specifications. Here’s a general overview of the production process of stainless U-bolts:

- Material Selection: Stainless steel is chosen as the raw material for its corrosion resistance, strength, and aesthetic appeal. The specific type of stainless steel (e.g., 304, 316) is selected based on the intended application and environmental conditions.

- Cutting: Stainless steel rods of the appropriate diameter are cut to the required length, depending on the size and specifications of the U-bolt.

- Bending: Once cut, the rods are then bent into the shape of a U using a bending machine or a press. The bending process ensures the uniformity of the curve and accurate spacing between the legs.

- Threading: The ends of the U-bolt are threaded using a threading machine, which cuts threads into the steel to allow for nuts to be screwed onto the ends.

- Heat Treatment: Depending on the specific requirements, the U-bolts might undergo a heat treatment process to enhance their mechanical properties, such as strength and toughness.

- Surface Finish: U-bolts undergo processes like polishing, passivation, or coating to improve their appearance, corrosion resistance, and overall performance. Passivation removes free iron from the surface, enhancing the natural corrosion resistance of stainless steel.

- Inspection: Once manufactured, the U-bolts undergo quality control to check for dimensional accuracy, surface quality, and any potential defects.

- Packaging: After inspection, the U-bolts are packaged along with nuts and washers (if part of the set) and prepared for shipping.

- Shipping and Distribution: The final product is then shipped to distributors, retailers, or directly to customers based on orders.

It’s worth noting that while the above steps provide a general idea of the process, specific manufacturing details might vary based on the production facility, equipment used, and the exact specifications of the U-bolts being produced.

What scenarios are stainless u bolts suitable for?

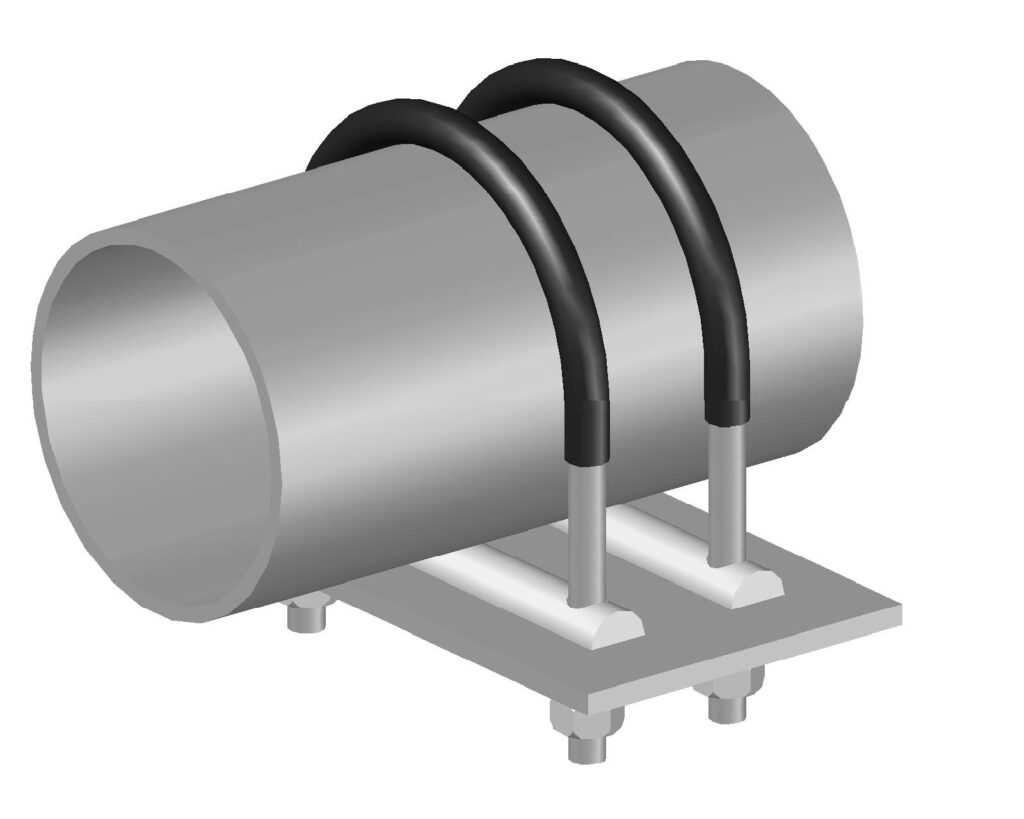

Stainless steel U-bolts are versatile fasteners suitable for a wide range of applications across various industries. Their design, which consists of a U-shaped bolt with threaded ends, makes them particularly useful in scenarios where secure attachment, stability, and corrosion resistance are required. Here are some common scenarios where stainless steel U-bolts are suitable:

- Pipe and Tube Fastening: U-bolts are commonly used to secure pipes, tubing, and conduit to support structures or mounting brackets. They provide a stable and adjustable connection for plumbing and electrical systems.

- Marine and Coastal Environments: Stainless steel U-bolts are highly corrosion-resistant, making them ideal for marine applications. They are used to secure equipment, cables, and components on boats, docks, and in coastal settings.

- Vehicle and Trailer Suspension: U-bolts are used to secure leaf springs in automotive and trailer suspension systems. They provide strength and stability to the suspension components.

- Construction and Building: U-bolts are used in construction to anchor beams, columns, and support structures. They are also employed for attaching hardware to steel and concrete.

- HVAC and Plumbing: In heating, ventilation, air conditioning (HVAC), and plumbing systems, U-bolts are used to secure ductwork, pipes, and related components.

- Antenna Mounting: U-bolts are utilized to secure antennas and satellite dishes to masts, towers, and other support structures.

- Exhaust Systems: Stainless steel U-bolts are commonly used to attach exhaust pipes and mufflers in automotive and industrial exhaust systems due to their resistance to high temperatures and corrosion.

- Railings and Fencing: U-bolts are used to attach handrails, guardrails, and fencing to support posts and structures.

- Industrial Equipment: U-bolts secure equipment and machinery in industrial settings, ensuring stability and minimizing vibration.

- Renewable Energy: They are used to secure solar panels and wind turbine components to mounting structures.

- Agriculture: U-bolts are employed in farming equipment and machinery for attaching components and securing loads.

- Telecommunications: U-bolts are used for mounting and securing antennas, satellite dishes, and communication equipment on towers and poles.

- Outdoor and Recreational Equipment: They are used in applications like bike racks, trailers, and camping gear for attachment and support.

Stainless steel U-bolts are valued for their durability, resistance to corrosion, and ability to provide a secure and adjustable connection. The specific application will determine the size, material grade, and configuration of the U-bolt used.